בת lĩnhת האפייה והחימום של מזון, תנורים הם ציוד חשוב ביותר. עם ההתקדמות המתמדת בטכנולוגיה, צצו שיטות אפייה חדשות, ותנור הקונברסיה עם זרימת אויר הוא אחד מהחדשניים שבהם. קיימים הבדלים משמעותיים בין תנור הקונברסיה לטיפוס הרגיל של תנור חימום בצינורות חימום במגוון תחומים. הבנה מעמיקה של ההבדלים הללו היא בעלי חשיבות רבה לחברות מזון, אופים מקצועיים וצרכנים המשאיפים לאיכות אפייה גבוהה. הדבר הזה עוזר להם בקבלת החלטות מיטביות בבחירת ציוד, אופטימיזציה של תהליכי עבודה ומשבח את תוצאת האפייה.

I. עקרונות חימום

תנור קונברסיה עם זרימת אויר

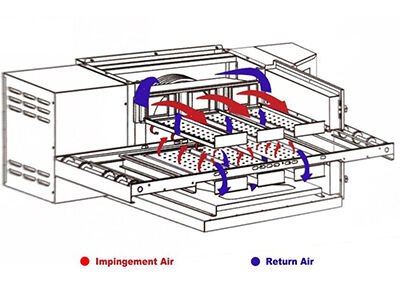

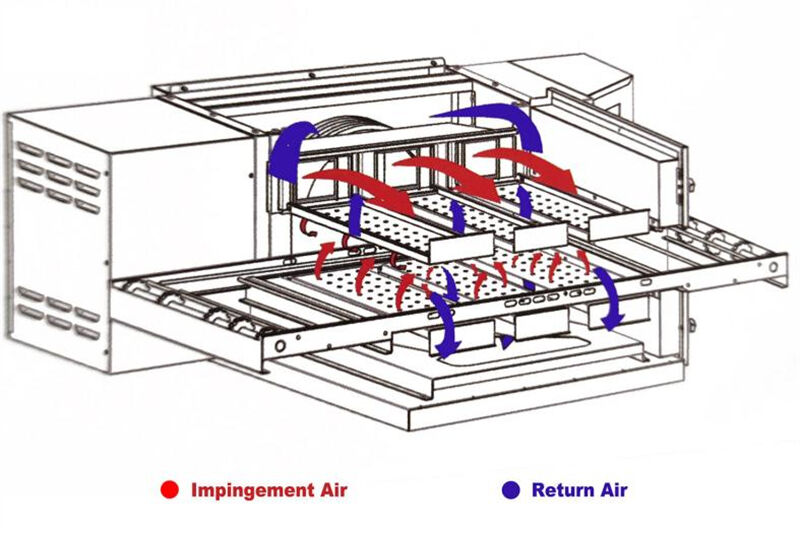

טכנולוגיית זרימת אויר תנור הפסולת המותקן בתנור מצויד במנוע פנימי שדוחס רציף אויר חם בלחץ גבוה לתוך התנור דרך תעלות הפסולת בשני הצדדים. טכנולוגיית הפגיעה באוויר הזו שומרת על הרטובות בתוך המזון, מה שעושה את המוצרים האופיים טריים ולذيיני טעם. וגם שומרת ביעילות על הרטובות בתוך המזון. מערכת סיבוב אויר חם מתקדמת חוסכת 30% בצריכת אנרגיה התהליך האופי מהיר, יציב וסטנדרטי. בנוסף, האויר החם האנכי מבטיח חימום וצביעה אחידה של המזון. מאחר שהאויר החם פוגע ישירות בפנימיות המזון, יעילות העברת החום היא גבוהה ביותר. הוא יכול להעביר חום במהירות אל המזון, ומכך מקצר את זמן האפייה באופן ניכר. חלק מהתנורים האופייניים מסוג Impingement Conveyor יכולים לאפות עד ארבע פעמים מהר יותר מאשר תנורים מסורתיים .

תנור צינור חימום מסורתי

חימום המבוסס על צינורות חימום תנור הפליזים הקלאסי מבוסס בעיקר על החום הנشعף שנוצר על ידי הפליזים כדי לחמם את המזון. הפליזים ממוקמים לרוב בחלק העליון והתחתון של התנור. על ידי חימום הפליזים, האוויר שבתוך התנור נתחמם, וזה בתורו מחמם את המזון. יעילות העברת החום בתנור הפליזים הקלאסי יחסית נמוכה מכיוון שהחום צריך לעבור ולהיבנות דרך האוויר כדי להגיע לפני השטח של המזון. שיטת החימום הזו איטית יחסית, מה שגורם למשך אפייה ממושך.

II. תוצאות האפייה

תנור קונברסיה עם זרימת אויר

הפצה מאוזנת של החום מכיוון שהאוויר החם יכול לפגוע ישירות בפני המזון, תנור ה- Impingement Conveyor יכול להשיג אפקט חימום אחיד יותר. ללא קשר לצורת המזון, הוא יכול להבטיח שכל החלקים של המזון מחוממים באופן שווה, וכך למנוע מצבים של חימום יתר מקומי או בישול לא מלא. תנור ה- Impingement Conveyor יכול לחמם במהירות את המזון, להפחית את אובדן הרוטב שבתוך המזון ולגרום לכך שהמזון יהיה עסיסי יותר יתרה מכך, עקב מהירות ההתחממות המהירה, שכבה קארמלית יכולה להיווצר במהרה על פני המזון, מה שעושה אותו טעים יותר.

תנור צינור חימום מסורתי

ביצועים גרועים בבישול מזון : אחידות החום של התנור הקלאסי פחותה יחסית. מאחר שהחום עובר בעיקר באמצעות קרינה וזרימה, קיים סיכון להתחממות מוגזמת או לבישול לא מלא באזורים מסוימים. לדוגמה, בעת אפיית מזון גדול, ייתכן שהקליפה החיצונית כבר נשרפה אך הפנימה עדיין לא מבושלת. בשל זמן האפייה הארוך יותר, בתנור קלאסי קיים סיכון גבוה יותר לאובדן מוגזם של רטיבות מהמזון, מה שעלול לגרום לו להיות יבש. יתרה מכך, עקב מהירות ההתחממות האיטית, תהליך היווצרות השכבה הקארמלית על פני המזון הוא איטי יותר, מה שעלול להשפיע לרעה על טקסטורת המזון.

III. תחום יישום

תנור קונברסיה עם זרימת אויר

ת התנור הקונבטי (Impingement Conveyor Oven) מתאים למגוון מזונות הדורשים אפייה מהירה, כגון פיצה, המבורגר ועוף טובל . המאכלים הללו דורשים לרוב השגה של תוצאה אופטימלית של אפייה בפרק זמן קצר, ובהתאם לכך תנור הפרסה רציף יכול לעמוד בדרישה זו. תנור הפרסה רציף נמצא בשימוש נרחב בתעשייה של מזון מהיר, תעשיית האפייה, והתעשייה העוסקת בעיבוד מזון . לדוגמה, במרכולי מזון מהיר, תנור הפרסה רציף יכול לאפות במהירות המבורגרים ועוף מטוגן, וכתוצאה מכך הוא מגביר את מהירות משלוח המאכלים. בתעשיית האפייה, תנור הפרסה רציף יכול לאפות במהירות לחמים ועוגות, וכך להגביר את יעילות הייצור.

תנור צינור חימום מסורתי

תנור טרומי מסורתי מתאים למגוון מאכלים הדורשים אפייה איטית, כגון בשר צלוי ותרנגול צלוי . המאכלים הללו לרוב דורשים אפייה בטמפרטורה נמוכה למשך זמן ממושך כדי להשיג טעם וטעים אידיאליים. התנור הטרומי המסורתי נמצא בשימוש נרחב במטבחים ביתיים, מסעדות, ובמלונות לדוגמה, במטבחים ביתיים, תנור הסקה מסורתי יכול לשמש לאפיית מגוון של מנות ביתיות. בрестורנים ובמלונות, תנור הסקה מסורתי יכול לשמש לאפיית מגוון מנות מתקדמות.

ד. עלות ושיפוץ

תנור קונברסיה עם זרימת אויר

עלות הציוד של תנור הסקה טורביני היא יחסית גבוהה מכיוון שהוא מחייב נווזלים ומערכות צינורות מיוחדים. בנוסף, מערכת הבקרה של תנור הסקה טורביני היא גם מורכבת יחסית ודורשת השקעה טכנולוגית גבוהה יותר. יתרה מכך, מערכת הבקרה של תנור הסקה טורביני צריכה גם תחזוקה קבועה כדי להבטיח את תפקודיה התקינים. אך, בזכות מערכת האוויר הטורביניית היעילה שלו, מהירות האפייה מהירה יותר, מה שמפחית את מספר התנורים הדרושים, חוסך שטח רציפה יקר, ופוחת את עלויות העסק .

תנור צינור חימום מסורתי

עלות ציוד: עלות הציוד של תנור חימום מסורתי נמוכה יחסית משום שמבנהו פשוט יחסית. תנור החימום המסורתי מורכב בעיקר מצינורות חימום, חלל התנור ומערכת הבקרה, עם עלויות ציוד נמוכות יחסית. עבודות התחזוקה העיקריות הן החלפת צינורות החימום וניקוי חלל התנור, עם עלויות תחזוקה נמוכות יחסית. עם זאת, בשל שיטת החימום הטרדיציונית שלו, מהירות האפייה איטית יותר, וטווח האפייה מוגבל יותר.

בהשוואת תנורי קונביישן בשרשרת מול תנורי צינור חימום טריידיאליים, עלות התחזוקה של תנור זה נמוכה יותר מזו של תנורי צינור חימום טריידיאליים. ראשית, הוא חוסך באנרגיה. חשבון החשמל היומי הוא ב-30% נמוך יותר ביחס לתנורי צינור חימום טריידיאליים. שנית, יש לו חיים שירות ארוכים יותר ביחס לתנורים טריידיאליים. שלישית, לתנורי קונביישן קל יותר לתחזוק ולטפל. החלקים שצריכים ניקוי הם לרוב תוספות ממתכת אל־חלד. בתנורים קלאסיים עם צלעות חימום גלויות, ייתכן ותלכוד הצלעות בכתמי שמן, מה שמקשה על הניקוי. יתרה מכך, ניקוי לא מספק עלול להוביל לחימום לא אחיד, מה שמפחית את איכות המוצרים האופיים, מעלה את אחוז הפירמות, ומעמיס על עלויות הפעלה של החנות, וכן הלאה.

EN

EN